Integrated oxygen generator for filling cylinders

Short Description:

Flow rate :5Nm3/hour (20cylinders per day with 24hours)

Purity :90%, 93% 95%

Usage: Filling cylinders

Warranty:24months

Main components: Air Compressor , Refrigerated Dryer, Air filters ,Oxygen generator , integrated on the skid , then no need any installation work

Product Detail

FAQ

Production Process

Product Tags

Integrated oxygen generator for filling cylinders

Oxygen making & cylinder filling system self-contained oxygen system can generate oxygen and fill the oxygen cylinders on site. As a completely standalone oxygen generation system, the Oxygen making & cylinder filling system is fully automated with compact and easy operation design, it can produce oxygen and fill the oxygen cylinders based on actual demand. The Oxygen making & cylinder filling system is one of the best solutions for the small gas businesses; it is affordable and offers a new profit center for your oxygen business.

PSA small Oxygen Generator for filling cylinder

An optional oil-free booster and filling ramp can be fitted to the Oxygen Plant to fill cylinders up to 200 bar. These cylinders can be distributed in the hospital or can be fitted to a manifold system as back-up in case of power failure.

The small oxygen generator is special design for small hospital which the paitients beds are less than 100pcs.The integrated small oxygen generator for filling cylinders don’t need any installtion and commission , giving it power , it will work atuomatically.

Technical Parameters

| Place of Origin | Brand | Model | Outlet Dew Point |

| Beijing China | Cape-Golden | CAOG-5 | -60ºC~-45ºC |

| Usage | Capacity | Purity | Material |

| small Oxygen generator | 5Nm3/hour(filling 20 cylinders per day) | 93%~99.5% | Carbon Steel/ Stainless steel |

| Delivery time | Working Pressure | Power Consumption | Structure |

| 20~40days | 4~200bar | 0.1kw | 4towers |

Advantage

* Most reliable technology

* More advanced and more economical air separation modules. extremely low power consumption

* Simple engineering design, Less components = lower maintenance cost

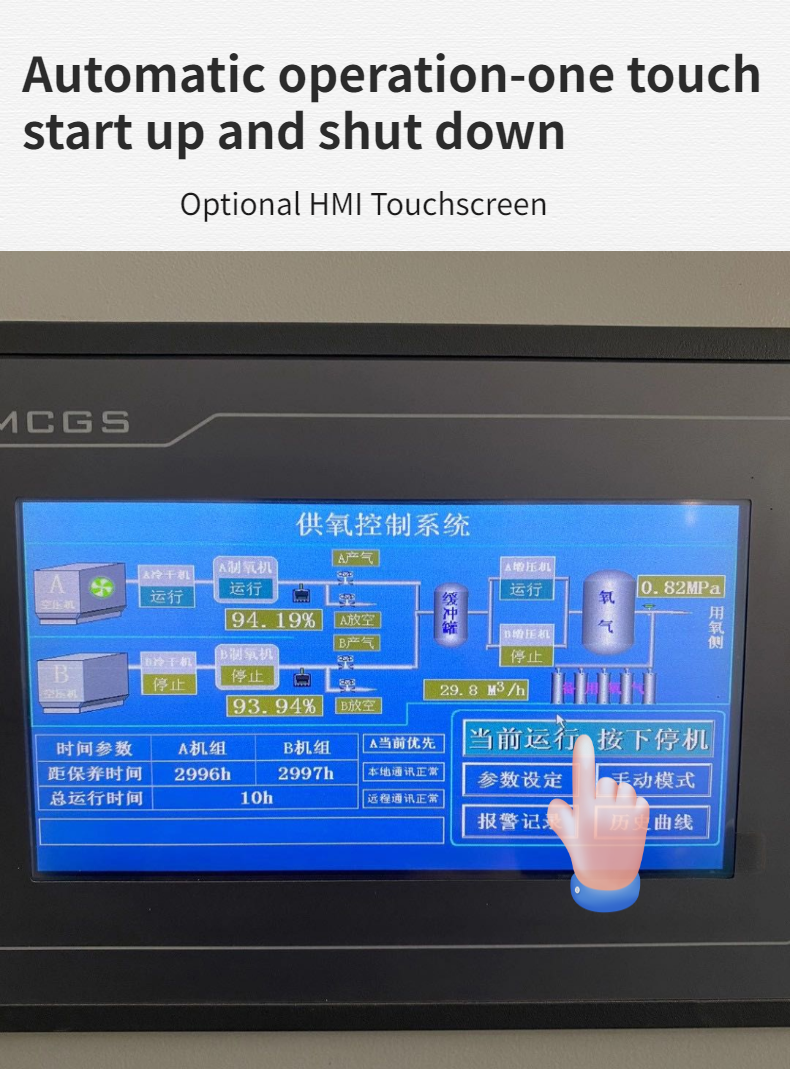

* Automated Operation.

* Turn-key solution and pre-commissioned.

* Skid mounted design, easy installation.

* Durable Molecular Sieve and Steel Structures ensures longer life.

* We take the one-on-one service mode , one customer–one saler–one engineer for evert set of oxygen generator .

1. Are you manufacturer or Trade Company?

1. Are you manufacturer or Trade Company?

We are OEM oxygen generator factory, founded in 2008.

2. What’s the order oxygen plant process?

a. Inquiry—provide us all clear requirements.

b. Quotation—official quotation form with all clear specifications.

c. Printing file— PDF, Ai, CDR, PSD, the picture resolution must be at least 300 dpi.

d. Contract confirmation—provide correct contract details.

e. Payment terms— T/T 30% in advanced, balanced before shipment.

f. Production—mass production

g. Shipping— by sea, air or courier. Detailed picture of package will be provided.

h. Installation and commissioning

3. How to get a prompt quotation?

When you send the inquiry to us, pls kindly send it with below technical information.

1) O2 flow rate: _____Nm3/hr

2) O2 purity: _____%

3) O2 discharge pressure: _____Bar

4) Voltages and Frequency : ______V/PH/HZ

5) Application:

|

Industry/fields |

Application |

|

Hospital |

Medical oxygen for breath |

|

Burning process (glass craft, ampoule making, thermal power) |

Enhances burning efficiency |

|

Ozone generation |

Raw material to make O3 |

|

Waste water disposal |

Oxidization of waste content |

|

Aquaculture |

Oxygen enriched water improves life of fishes |

|

Fermentation |

Better atmosphere for fermentation |

|

Diving, mountaineering, |

For breathing |

|

High-altitude flight, interplanetary flight, civil aviation |

For breathing |

|

Cutting, welding |

Burns to produce heat |

|

Engineering Blasting |

To make liquid oxygen explosive |

|

Metallurgy |

Ironmaking, steelmaking |

|

Oxygen enriching |

Bar, meeting room, office, dorm, homes |

|

Mining |

Reacts with minerals to increase separation rate |

|

Chemical engineering |

To make vitriol, nitric acid, etc. |

|

Paper and pulp |

Pulp bleaching |