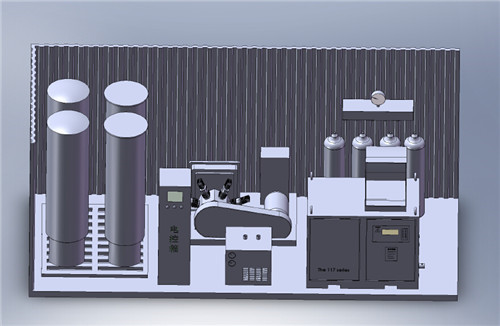

Movable Containerized type oxygen generator

Short Description:

Flow rate :15Nm3/hour

Purity : 95%

Container size :20′feet

Usage: Filling cylinders

Warranty:24months

Main components: Air Compressor , Refrigerated Dryer, Air filters ,Oxygen generator , etc.

Product Detail

FAQ

Production Process

Product Tags

Movable Containerized type oxygen generator

Oxygen generation system produces oxygen at purity about 93~95%, and the capacity can be from 1~300Nm3/hour. The system incorporates an Atlas Copco screw air compressor, JMEC refrigerated air dryer and Parker filters, SunnyYoung oxygen generator air buffer tank, oxygen buffer tank, oxygen booster.

Work Principle

The PSA oxygen technology process for the generation of oxygen gas from compressed air utilizes the ability of Zeolite Molecular Sieve (ZMS) to absorb mainly nitrogen. While nitrogen concentrates in the pore system of the ZMS, the qualified purity of oxygen will be produced.

Our Advantage

Strong technology research and development team

Cape Golden relies on the technology advantage of Tsinghua University, Chinese Academy of Sciences and China Agricultural University, with more than ten years experience of air separation and agricultural irrigation technology, now we could meet customers’ different requirements in various fields, we always insist on providing economic, reliable, efficient and standard instruments and service.

Perfect production quality assurance measures

Beijing Cape Golden Gas System Company LTD., conducts quality control management in production process, in accordance with the ISO9001: 2000 quality management system standard, including:

1. Clear the customer’s requirements, provide perfect, reasonable technology solutions

2. contract review

3. design control

4. Spare parts procurement, outsourcing processing control

5. manufacturing control

6. The factory inspection

6. Equipment packing and shipping control

Delicate and careful on-site training and after-sales service

Cape Golden provides on-site training for each sold product and after-sales service, on-site training is for unlimited time, for the customers to completely understand the indicators of the products.

After-sales service hotline for 7*24 hours, to guide the customer problems at any time. The 37 after-sales service personnel provide on-site service for global customers. Since the Company’s establishment, there is not one case of after-sales service complaint, our company gets customers in various areas of the world high praise.

| PSA Oxygen generator | ||

| Capacity (Nm³/h) | Purity(%) | Model |

| 1 | 93~99 | CAOG-1 |

| 2 | 93~99 | CAOG-2 |

| 4 | 93~99 | CAOG-4 |

| 5 | 93~99 | CAOG-5 |

| 6 | 93~99 | CAOG-6 |

| 8 | 93~99 | CAOG-8 |

| 10 | 93~99 | CAOG-10 |

| 15 | 93~99 | CAOG-15 |

| 20 | 93~99 | CAOG-20 |

| 25 | 93~99 | CAOG-25 |

| 30 | 93~99 | CAOG-30 |

| 40 | 93~99 | CAOG-40 |

| 50 | 93~95 | CAOG-50 |

| 60 | 93~95 | CAOG-60 |

| 100 | 93~95 | CAOG-100 |

| 200 | 93~95 | CAOG-200 |

| CA® PSA Oxygen generator for filling cylinders | ||

| Qty of cylinders (pieces/day) | Purity(%) | Model |

| 12 | 93~99 | CAFS-3 |

| 20 | 93~99 | CAFS-5 |

| 40 | 93~99 | CAFS-10 |

| 60 | 93~99 | CAFS-15 |

| 80 | 93~99 | CAFS-20 |

| 100 | 93~99 | CAFS-25 |

| 120 | 93~99 | CAFS-30 |

| 200 | 93~99 | CAFS-50 |

| 320 | 93~99 | CAFS-80 |

| 400 | 93~99 | CAFS-100 |

| Remark: Cylinders capacity is 6m3 | ||

| For more details , pls feel free to contract with us. | ||

1. Are you manufacturer or Trade Company?

We are OEM professional High efficient Skid mounted oxygen plant cost factory, founded in 1997.

2. What’s the order oxygen plant process?

a. Inquiry—provide us all clear requirements.

b. Quotation—official quotation form with all clear specifications.

c. Printing file— PDF, Ai, CDR, PSD, the picture resolution must be at least 300 dpi.

d. Contract confirmation—provide correct contract details.

e. Payment terms— T/T 30% in advanced, balanced before shipment.

f. Production—mass production

g. Shipping— by sea, air or courier. Detailed picture of package will be provided.

h. Installation and commissioning

3. How to get a prompt quotation?

When you send the inquiry to us, pls kindly send it with below technical information.

1) O2 flow rate: _____Nm3/hr

2) O2 purity: _____%

3) O2 discharge pressure: _____Bar

4) Voltages and Frequency : ______V/PH/HZ

5) Application:

|

Industry/fields |

Application |

|

Hospital |

Medical oxygen for breath |

|

Burning process (glass craft, ampoule making, thermal power) |

Enhances burning efficiency |

|

Ozone generation |

Raw material to make O3 |

|

Waste water disposal |

Oxidization of waste content |

|

Aquaculture |

Oxygen enriched water improves life of fishes |

|

Fermentation |

Better atmosphere for fermentation |

|

Diving, mountaineering, |

For breathing |

|

High-altitude flight, interplanetary flight, civil aviation |

For breathing |

|

Cutting, welding |

Burns to produce heat |

|

Engineering Blasting |

To make liquid oxygen explosive |

|

Metallurgy |

Ironmaking, steelmaking |

|

Oxygen enriching |

Bar, meeting room, office, dorm, homes |

|

Mining |

Reacts with minerals to increase separation rate |

|

Chemical engineering |

To make vitriol, nitric acid, etc. |

|

Paper and pulp |

Pulp bleaching |