PSA Nitrogen Generator For Laser Cutting

Short Description:

Product Detail

Product Tags

PSA Nitrogen Generator For Laser Cutting

Laser cutting with nitrogen is intended for applications where oxidation is not wanted. For example, an oxide layer can cause paint to adhere less strongly on non-alloy steel. If non-alloy steel is painted after cutting, the cutting gas should be nitrogen. Weldable steel components laser cut with oxygen will not pass the bending test. Stainless steel loses its corrosion resistance when cut with oxygen, and aluminum pieces cut with oxygen have an uneven and burred cut surface.

When nitrogen is used as the cutting gas, the laser beam melts the material, and the nitrogen blows away the molten material from the cutting groove. Since no exothermic reaction takes place, the cutting speed is much slower than when cutting with oxygen. To ensure a burr-free cut edge, the laser beam must usually be focused on the bottom surface of the plate.

The advantages of nitrogen use in Laser Cutting include:

Nitrogen is inert, dry, non-flamable gas used to remove oxygen.

Prevents Oxidation, scaling or discolorization

Rapidly removes molten metal or dross from cutting zone

Protects laser optics, mirrors and lenses

Gives edges better adhesion for Paint

Gives welded edges improved bend strength

Removes particulate from beam path reducing distor

Cape-Golden Nitrogen Generator produces Nitrogen at purity about 93~99.999%, and the capacity can be from 1~300Nm3/hour.

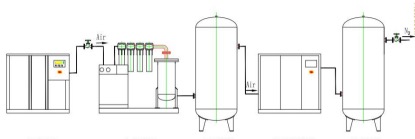

PSA Nitrogen Generator Work Principle

PSA nitrogen technology utilizes two towers which are filled with carbon molecular sieve (CMS). Compressed air enters the bottom of one tower. While the smaller oxygen molecules are adsorbed by the CMS, the larger nitrogen molecules pass through the sieve and are stored. Once the CMS of the working tower is saturated with oxygen, the regeneration of the CMS in the tower starts to work by depressurizing, and while another tower is switched to start the process over again.

Specification&Selection

|

Cape-Golden PSA Nitrogen generator |

||

|

Capacity (Nm³/h) |

Purity(%) |

Model |

|

5 |

95 |

CANL-5 |

|

99 |

CANP-5 |

|

|

99.5 |

CANG-5 |

|

|

99.9 |

CANH-5 |

|

|

99.99 |

CANZ-5 |

|

|

99.999 |

CANHZ-5 |

|

|

10 |

95 |

CANL-10 |

|

99 |

CANP-10 |

|

|

99.5 |

CANG-10 |

|

|

99.9 |

CANH-10 |

|

|

99.99 |

CANZ-10 |

|

|

99.999 |

CANHZ-10 |

|

|

20 |

95 |

CANL-20 |

|

99 |

CANP-20 |

|

|

99.5 |

CANG-20 |

|

|

99.9 |

CANH-20 |

|

|

99.99 |

CANZ-20 |

|

|

99.999 |

CANHZ-20 |

|

|

30 |

95 |

CANL-30 |

|

99 |

CANP-30 |

|

|

99.5 |

CANG-30 |

|

|

99.9 |

CANH-30 |

|

|

99.99 |

CANZ-30 |

|

|

99.999 |

CANHZ-30 |

|

|

50 |

95 |

CANL-50 |

|

99 |

CANP-50 |

|

|

99.5 |

CANG-50 |

|

|

99.9 |

CANH-50 |

|

|

99.99 |

CANZ-50 |

|

|

99.999 |

CANHZ-50 |

|

|

100 |

95 |

CANL-100 |

|

99 |

CANP-100 |

|

|

99.5 |

CANG-100 |

|

|

99.9 |

CANH-100 |

|

|

99.99 |

CANZ-100 |

|

|

99.999 |

CANHZ-100 |

|

|

200 |

95 |

CANL-200 |

|

99 |

CANP-200 |

|

|

99.5 |

CANG-200 |

|

|

99.9 |

CANH-200 |

|

|

99.99 |

CANZ-200 |

|

|

99.999 |

CANHZ-200 |

|

|

300 |

95 |

CANL-300 |

|

99 |

CANP-300 |

|

|

99.5 |

CANG-300 |

|

|

99.9 |

CANH-300 |

|

|

99.99 |

CANZ-300 |

|

|

99.999 |

CANHZ-300 |

|

|

500 |

95 |

CANL-500 |

|

99 |

CANP-500 |

|

|

99.5 |

CANG-500 |

|

|

99.9 |

CANH-500 |

|

|

99.99 |

CANZ-500 |

|

|

99.999 |

CANHZ-500 |

|

|

1000 |

95 |

CANL-1000 |

|

99 |

CANP-1000 |

|

|

99.5 |

CANG-51000 |

|

|

99.9 |

CANH-1000 |

|

|

99.99 |

CANZ-1000 |

|